CrazyDrill / CrazyMill Hexalobe

Saving time while increasing

precision and quality

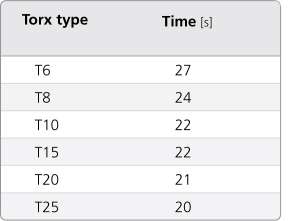

Shorter machining time* -

up to 50% faster

- Drilling and chamfering in one step (save one operation for chamfering)

- Short cycle time for milling thanks to high removal rate (ap and ae), i.e. high-angle milling with helical interpolation

For example: milling in Titanium, version 3.5 x d, p = 0.4 x d (quality and cycle time depending on cutting parameter and machine conditions)

*Comparison based on drilling/milling tools available in the market for stainless steel and titanium and machining parameters recommended by manufacturers.

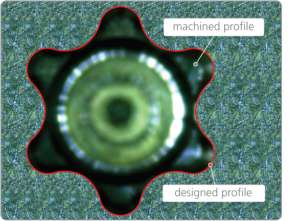

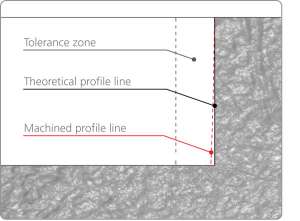

High degree of precision

- High degree of precision of profiles

- Thanks to robust carbide shank

- Thanks to new carbide with edge chipping resistance

- Very accurate perpendicularity

- Thanks to high stiffness of the tool

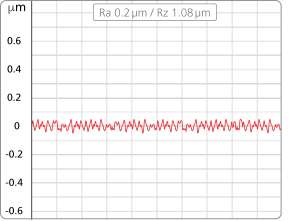

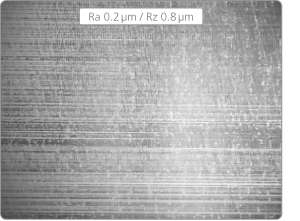

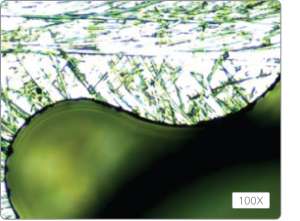

Excellent surface quality

- High quality of chamfer surface (lowest roughness)

- Excellent surface quality of hex lobular socket

- Thanks to axial removal rate and vibration free milling (robust carbide shank)

- Machining profile with minimal burrs - nearly burr free

Long tool life

and process accuracy

- Up to 3 times longer tool life*

- Thanks to good chip breaking when drilling

- Thanks to new heat- and wear-resistant coating

*Comparison based on drilling/milling tools available in the market for stainless steel and titanium and machining parameters recommended by manufacturers.

Low production costs

- Thanks to faster machining

- Thanks to longer tool life

- Thanks to combined drill: one single tool for pre-hole drilling, chamfering and deburring

Coordinated and complete drilling and milling program

- CrazyDrill Hexalobe – the new combined drill for „TORX®“ shapes (hex lobular socket)

- Pre-hole drilling and 120° chamfer in one single step

- Tip angle 140°

- Two cutting geometries: for machining of Titanium or Stainless Steel and Cobalt Chrome

- For profiles from T4 – T30 (drilling diameter from 0.9 to 3.8 mm, [.035“ - .150“])

- Chrome free coating to avoid cross contamination on medical parts

- Other dimensions available on request

- CrazyDrill Hexalobe Flat – the new flat drill for „TORX®“ shapes (hex lobular socket)

- Pre-hole drilling and 120° chamfer in one single step

- Tip angle 180°

- One cutting geometry: for machining of Titanium, Stainless Steel and Cobalt Chrome

- For profiles from T4 – T30 (drilling diameter from 0.9 to 3.8 mm, [.035“ - .150“])

- Chrome free coating to avoid cross contamination on medical parts

- Other dimensions available on request

- CrazyMill Hexalobe – the new endmill for „TORX®“ shapes (hex lobular socket)

- Milling with helical interpolation (with max. pitch 0.8 x d) i.e. side milling (with stepover max 0.5 x d)

- Three cutting geometries: for vibration free machining of Titanium or Stainless Steel or Cobalt Chrome

- For profiles from T4 – T30 (milling diameter from 0.2 to 1.0 mm, [.008“ - .039“])

- Two lengths: 3.5 x d and 5 x d

- Number of flutes:

- Diameter range 0.2 – 0.3 mm (.008“ - .012“): 3 flutes

- Diameter range 0.4 – 1.0 mm (.016“ - .039“): 4 flutes

- New carbide: special micro-grain carbide with high stiffness and edge chipping resistance, developed for high profile precision

- Chrome free coating to avoid a cross contamination on medical parts

Special characteristics

- New concept: drilling – chamfering – milling – deburring: four operations in three steps with two tools

- Highest efficiency and short machining time for Titanium, Stainless Steel and Cobalt Chrome

- Three specific geometries for the machining of Titanium, Stainless Steel and Cobalt Chrome: CrazyDrill Hexalobe Flat - one geometry; CrazyDrill Hexalobe - two geometries; CrazyMill Hexalobe - three geometries

- High-performance coating eXedur SNP, chrome free, heat and wear resistant prevent buildup of edges and guarantees optimum chip flushing

- Micro-grain carbide with high stiffness and edge chipping resistance

- Highest surface quality and profile matching

- Mikron Tool produces all tools with highest repeat precision. Hence the user will benefit from long term stable production conditions (stable process and machining precision)