Customer-specific drills

Customer-specific drills

Your needs and requirements

Mikron Tool produces carbide drilling tools according to your needs and requirements.

- You determines the operating conditions and the designated result and we define a matching tool for you.

- You already know what tool you want? We will gladly accept this input as well and grind the tool using your drawing.

- You've seen one of our drilling tools from the CrazyDrill family and you need it in a special length, in a special diameter or for the use of a special material? We will make you a tool with the geometry that meets your needs.

- You have a new project and you need tools for optimal machining of a part? We will help you with the design, definition of geometries and determining the best parameters.

Click here and send us your inquiry

Our offer

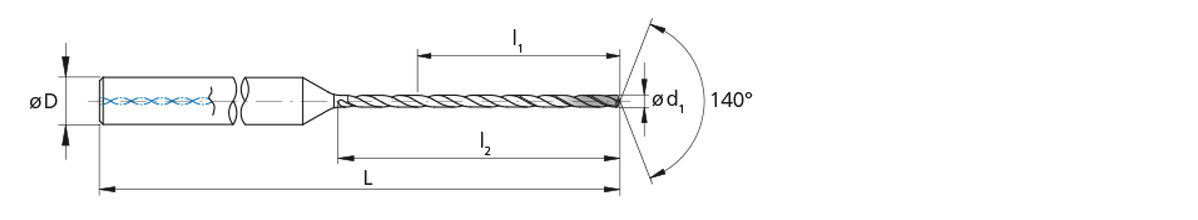

Mikron Tool offers its customer-specific tools within this range:

- Diameter min.: 0.1 mm (.0039“)

- Diameter max.: 32.0 mm (1.260”), please contact us for larger diameters

- Max drill length: 415 mm (16.339”)

- Achievable tolerance of tool diameters: ± 0.5 µm (.00002”)

- Best concentricity between shaft and tool diameters: 2 µm (.00008”)

- Chamfer and point angle: according to need

- Step drill: see customer-specific step drill

- Number of cutting edges: 1, 2 or 3

- Cutting direction: right-hand drill or left-hand drill

- Conical drill

- Drill material: tungsten carbide, grade selection depends on the application

- Material to be machined: drill for steel, corrosion resistant steels, i.e. stainless steel, titanium/titanium alloys, superalloys or heat-resistant steels such as Inconel or Hastelloy, CrCo alloys, drill bits for hardened steel up to 55 HRC, aluminum/aluminum alloys, brass, copper, cast materials, etc.

- Cooling:

- Drill with internal cooling through holes following the helix up to the drill tip

- Drill with internal cooling through straight holes in the shaft

- Drill for external coolant supply

- Type of shaft:

- Cylindrical DIN 6535 HA

- Cylindrical DIN 6535 HE (Whistle Notch)

- Cylindrical DIN 6535 HB (Weldon)

- More upon request

- Coatings: Various, selection according to application

- Treatments: Cutting edge preparation, polishing of flutes

Our features

High degree of precision / quality

The tools are fabricated with the highest degree of precision and repeat accuracy. This allows users to produce their end products reliably and with the desired precision.

Short machining time

High feed rates are possible because of the use of high-grade carbide blanks, innovative cutting geometries and cooling systems as well as high-performance coatings always adapted to the specific application (for example, the material to be machined). The machining time is therefore extremely short.

Long tool life

The ideal combination of carbide, coating method, quantity and geometry of cutting edges combined with the machining parameters we recommend guarantees optimal tool life.

High degree of reliability

This is guaranteed at Mikron Tool especially by stable and manufacturing processes with a very high degree of repeat accuracy. A unique identification code on each tool shaft is used for tracking and quality Assurance.

Low machining costs

The use of Mikron Tool solid carbide drill bits translates to stable and smooth machining. Machining costs are kept low due to short machining times, long tool life and the highest degree of precision.

Reduce tool costs in an

environmentally-friendly manner!

Find out about tool recycling options when purchasing new tools. Regrinding tools is not only good for the environment but can reduce tool costs further. All parameters are taken from the manufacturing process for new tools: the same grinding machine, the same grinding wheels, the same grinding programs and a new original coating, new surface treatment and final quality control after the sharpening. This gives users the assurance that the quality of the re-ground tools is identical and they can continue machining with the same cutting values.

Interested? Contact us!

Tools from Mikron Tool (whether standard or customized) are fabricated with the highest quality and repeat accuracy. Based on our many years of experience and expertise in the machining of "difficult materials" (for example, stainless steels), we can offer you profitable solutions. The result for you is a perfectly functioning tool during the entire production lifecycle of your tool.

Click here and send us your inquiry