Mikron Tool invests in the future

-

New building in Agno: Extension of production area by 1000 m2

We take a look back – this once. 2018: Mikron Tool is bursting at the seams; our production area is at full capacity. As an interim solution, Production Management relies on lean production methods: the same area, more machines, more output with strict compliance to safety standards for exhaust air purification and personal protection. But the volume of orders keeps rising steadily. Even more capacity is required. A new production facility must be built. That was early 2019.

Everything in a single place

A decision is reached quickly after conclusion of cost-benefit analysis. From a financial standpoint, it makes sense to build yourself. An extension adjacent to the current building will be constructed. Building land is available. The major advantage for production and logistics: everything remains in one place.

The project requires careful calculation and planning. Outsourcing of the central grinding oil feed for the machines and the associated fire safety measures were particularly challenging. After the construction project was checked and approved by nine different authorities, we received planning permission. After a planning phase of nine months, the ground-breaking ceremony took place on December 2, 2019.

Everything firmly anchored

The work on geotechnical ground anchoring was complex. Due to the deep sandy loam layers (former wetlands), micropiles with a diameter of 12 cm were driven into the ground to a depth of 25 m. 27 piles in total, essential to ensure the load-bearing capacity of the building. Cement was shot through these at high pressure, forming a plug at the lower end of the piles, which stabilise these pillars in the ground. This means the building stands on solid foundations.

A real highlight: during construction, Mikron Tool replaced the old oil heating system with a state-of-the-art mixing plant for heat recovery from production. The waste heat from the oil used in grinding processes and from the compressors, which generate the compressed air for the CNC machines, is recycled using heat exchangers to provide hot water for the entire building complex at Agno. Since the beginning of December, Mikron Tool has stopped using fossil fuels.

And it didn't stop there. The outdated refrigeration system was also completely replaced during construction. Thanks to this upgrade, 350,000 kWh of electricity will be saved annually. Careful and more effective use of resources benefits society as a whole. This is great news for our partners who can be confident that they are working with a company committed to tangible environmental sustainability.

In the end everyone wins

How could it be otherwise: the construction work was delayed by the COVID pandemic. However, thanks to excellent project management by the Mikron Tool management team and Paolo Ruggia, infrastructure consultant at Mikron Switzerland AG, Agno, the project progressed swiftly.

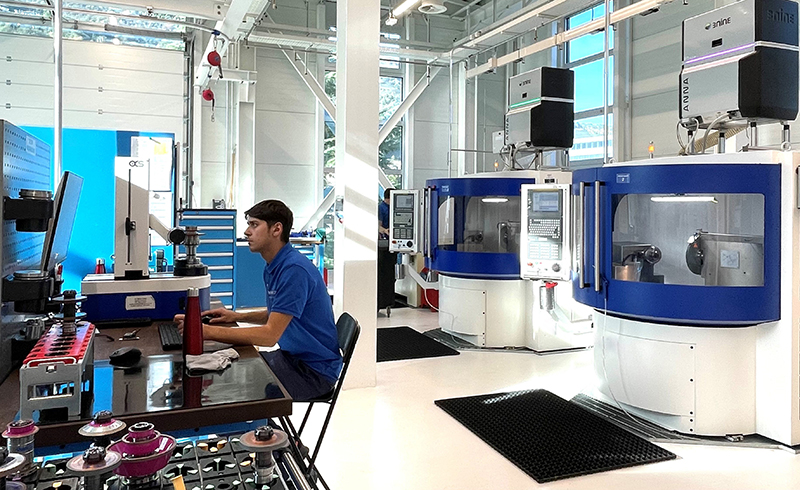

A new two-storey, fully air-conditioned production hall with a total of 1000 m2 is now ready. The total usable area of Mikron Tool’s production has increased to 3500 m2. Our production employees can breathe a sigh of relief: there is enough space again. The department for the production of micro tools and the grinding wheel preparation have already moved to the new building.

Official inauguration

On October 19, 2022, the time had finally come. The new COO Elio Lupica inaugurated the new production facility of Mikron Switzerland AG, Division Tool, in the presence of the local authorities and representatives of the umbrella organizations AITI and Swissmem.

With the expansion of the production facility in Agno, Mikron Tool has created additional production capacity. This is good news for the region because it creates new jobs. Of course, our partners also benefit and will soon be gratified by shorter delivery times. They can continue to rely on a partner who invests in the future with vision and focuses on sustainability. This project shows that Mikron Tool is focusing on efficiency as well as growth.

Once again completely crazy, typical Mikron Tool.