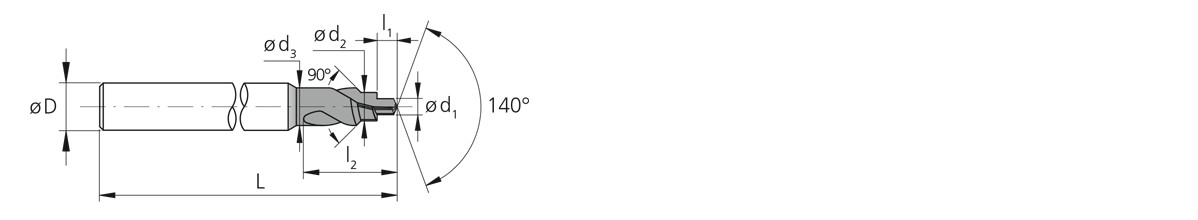

Crazy Tools

Cutting solutions for professionals

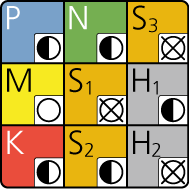

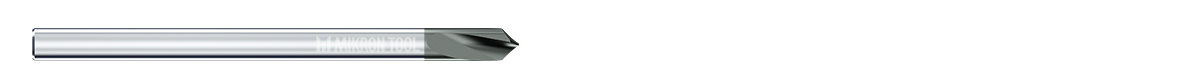

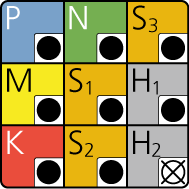

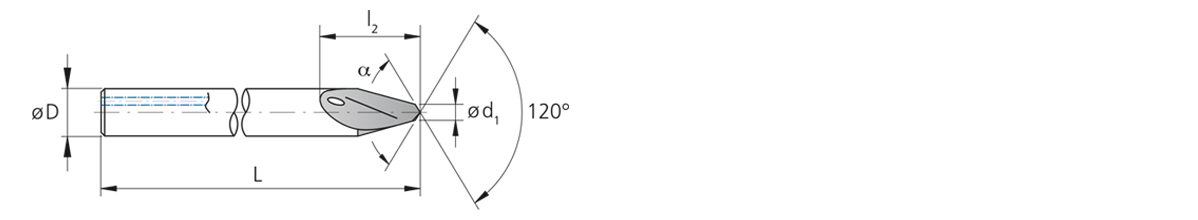

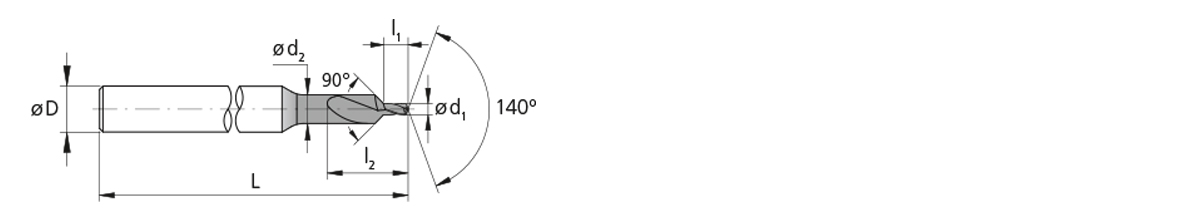

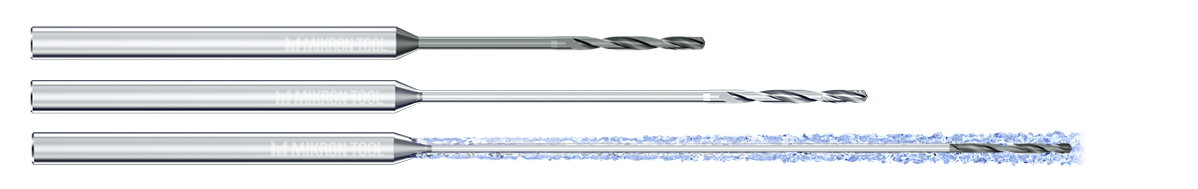

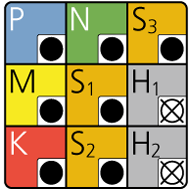

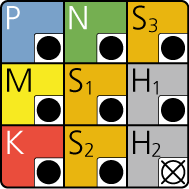

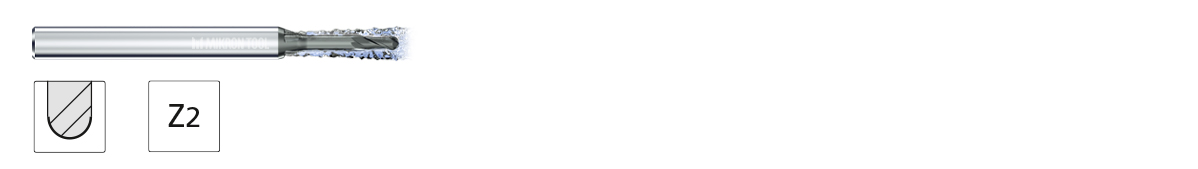

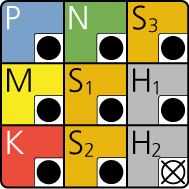

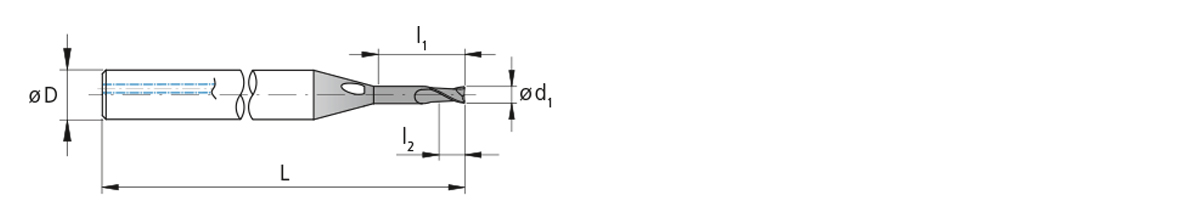

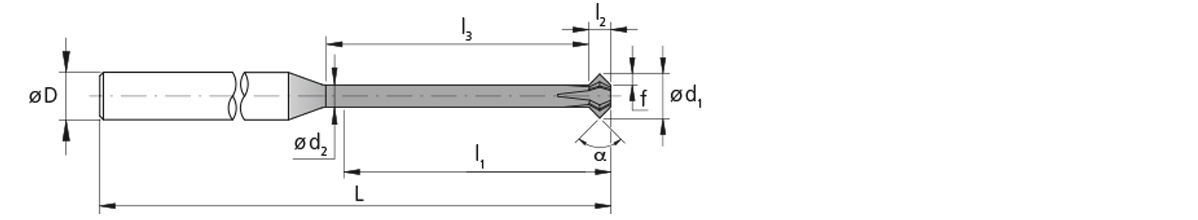

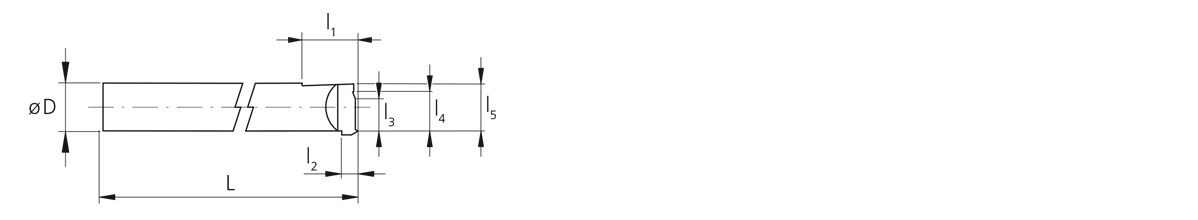

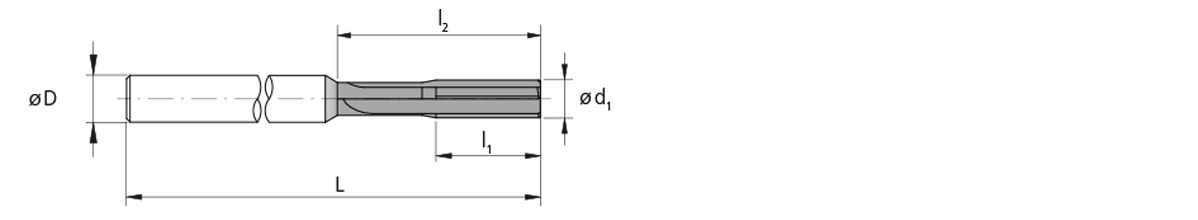

Mikron Tool offers catalog tools of tungsten carbide for centering, chamfering and drilling, for milling and deburring in the diameter range from 0.1 to 8 mm (.004” to .315”).

In the area of customer-specific tools, the offer comprises the centering and chamfering, milling, turning, grinding or deburring and up to complex combination tools in the diameter range between 0.1 mm and 32 mm (.004” and 1.260”).