Machining gets easier with new “crazy” high performance cutting tools

- Mikron Tool, the Swiss manufacturer of cutting tools for the micro-machining of difficult materials, proudly presents new solid carbide tools at the EMO 2025.

Mikron Tool, the Swiss manufacturer of cutting tools for the micro-machining of difficult materials, proudly presents new solid carbide tools at the EMO 2025. The new corner radius CrazyMill Cool CF endmills, the new CrazyDrill Flex Titanium ATK for deep-hole drilling of alloyed titanium components, and CrazyMill Knee, a full package of high-performance endmills and strategies for knee machining. Mikron Tool confirms once again its absolute leadership in high-performance micro-machining applications.

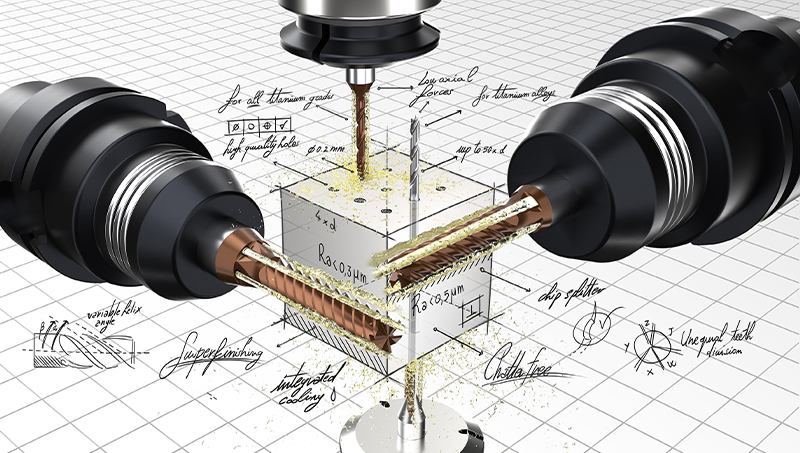

CrazyMill Cool CF - Chatter-free endmills with new corner radius profiles

The CrazyMill Cool CF is a high-performance endmill designed for very high machining rates and capable of handling very challenging, delicate component structures. A perfect balance between cutting angle, clearance angle, and cutting-edge conditioning, results in low radial cutting forces, and thus ensures the best form and squareness tolerances even at maximum axial engagement.

Its specific cutting geometry, combined with a dynamic milling process, makes it the ideal endmill for delicate, thin-walled parts, or for parts that are not stable when clamped, which is a particularly common occurrence in the medical field (bone plates) and aerospace industry (structural components), as well as the watch industry. CrazyMill Cool CF is also very efficient, and precise, yielding an excellent surface quality (Ra 0.5 µm or better). It runs quietly when cutting grooves, pockets, or other large volume machining tasks.

The endmill is available immediately in diameters from 1 to 8 millimeters and in two different full cutting lengths (3 x d and 4 x d).

Today, the new CrazyMill Cool CF endmills cutters are available with various corner radius profile options.

Sharp corners in machined parts can lead to increased cutting forces, concentrated stress, and ultimately, cracks or failures. While on the one hand square mills can achieve a profile with a sharp corner (sometimes requested by customer design), on the other hand, corner radius endmills are designed to mitigate stress by distributing forces more evenly across the corner, significantly reducing the likelihood of part damage and extending tool life.

Compared to square endmills, corner radius endmills offer superior durability. Their design makes them less prone to chipping, fracturing, and wear because cutting forces and pressure are more evenly distributed along each cutting edge.

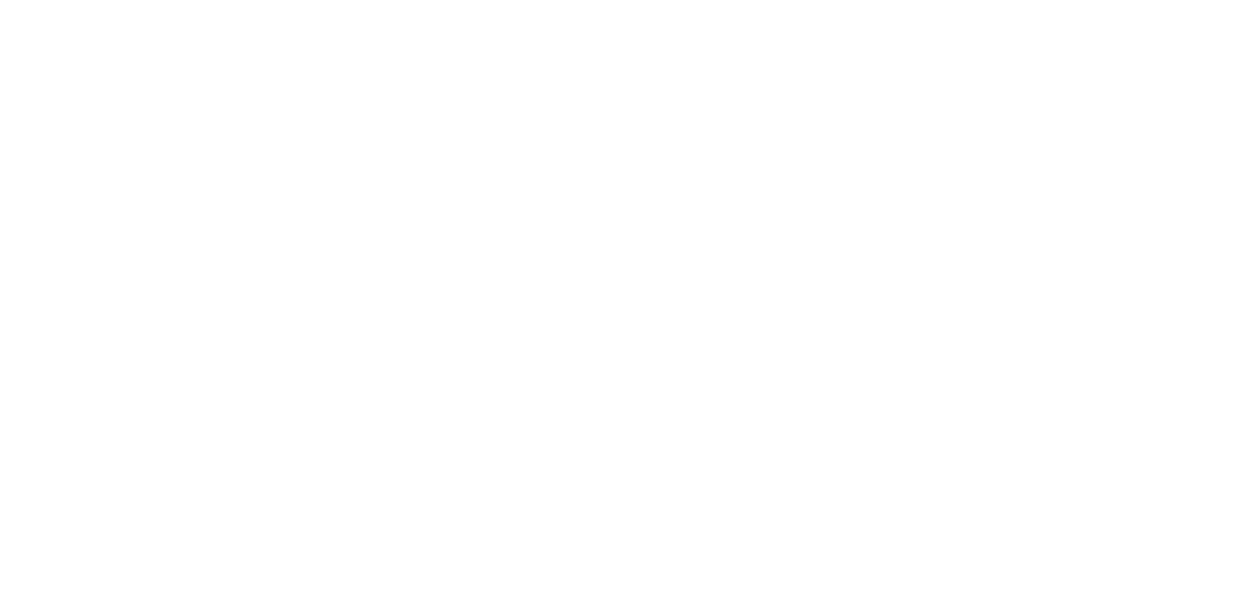

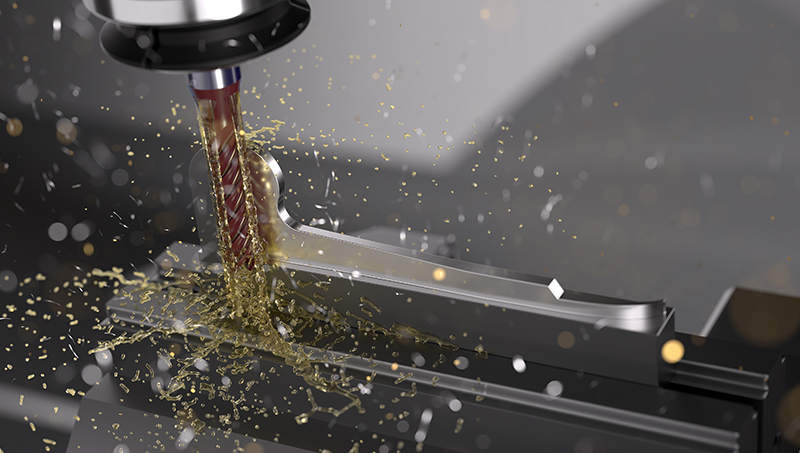

Micro deep hole drilling of titanium alloys with the new CrazyDrill Flex Titanium ATK

With the new CrazyDrill Flex Titanium ATK, Mikron Tool has developed a high-performance drill that guarantees optimal deep-hole drilling for alloyed titanium. This is made possible by a specifically designed cutting geometry and corresponding pecking drill processes, which keep chips short and enable a safe chip removal.

Titanium Grade 5 (Ti-6Al-4V) is a Titanium alloy with 6% Aluminum and 4% Vanadium and is commonly known as Ti 6Al-4V. It’s the most widely used titanium alloy because of its high strength-to-weight ratio, excellent fatigue resistance, and good corrosion resistance. These properties have made it increasingly popular in many industries. Its growing adoption implies a rising demand for high-performance drilling tools. However, the material's poor machinability — especially in deep hole drilling applications — presents significant challenges. Chip control, bore straightness, and hole roundness are particularly difficult to maintain.

These market demands, especially in the medical field (e.g. drilling of cannulated bone screws and ophthalmic needles), have driven the development of stable and high-performance deep hole drilling solutions capable of overcoming these limitations.

The newly developed CrazyDrill Flex Titanium ATK for deep hole drilling of alloyed titanium have the following advantages and properties:

- Excellent self-centering

- Highest process reliability

- Perfect chip evacuation

- Reduced material adhesion

The new CrazyDrill Flex Titanium ATK allows a much shorter drilling time than other drilling technologies, such as single-lip drills, micro-erosion or laser methods. This product is available in

- 182 articles,

- Lengths 30xd and 50xd

- Diameters from Ø0.3 mm to Ø2.0 mm in 0.01 mm increments

- -0.003/-0.006

- Web thinning for optimized self-centering

- 30° helix angle

- Optimized flutes for reduced material adhesion and improved chip evacuation

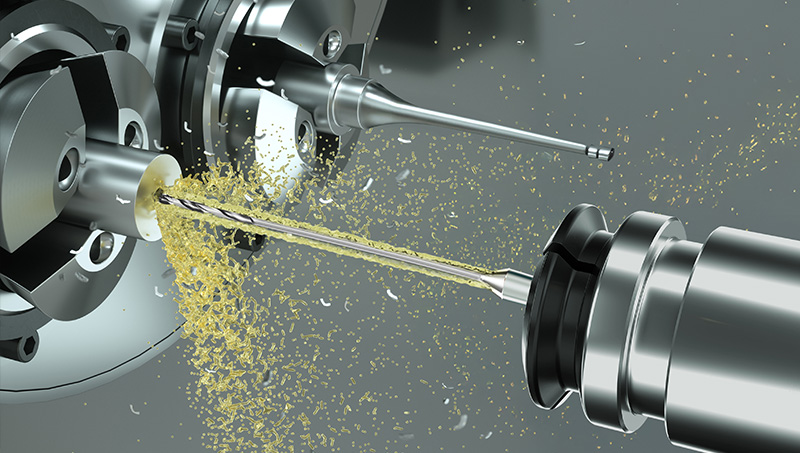

CrazyMill Knee: a full package of high-performance endmills and strategies for knee machining

Knee implant manufacturers are facing a three-fold challenge: the need to machine faster, reduce costs, and uphold high precision as implants become increasingly customized for patients. Specific components pose their own difficulties. Tibial trays demand burr-free surfaces and an excellent finish to ensure a seamless connection with the rest of the implant. The bearing insert, which links the tibial tray to the femoral implant, must precisely match the intricate curves of the femoral condyle surfaces. Machining femoral components is particularly challenging due to both their complex shapes and the materials used.

The increasing use of high-grade materials like cobalt-chromium alloys in both tibial and femoral components adds another layer of complexity to the manufacturing process. On the one hand, they are preferred because of their excellent biocompatibility, chemical stability, and strength and wear resistance. On the other hand, their strength, high hardness (450-600 HV - 40-50 HRC), and toughness make CoCr alloys particularly difficult to machine. These material properties commonly result in machining challenges such as shortened tool life, poor surface finish, and built-up edge.

On top of those tough material properties, femoral components usually include oxides, melting residues, or 3D printing supports to be removed, which can be particularly hard, abrasive, and difficult to remove.

Leveraging years of experience and a deep understanding of these industry hurdles, Mikron Tool assists knee implant manufacturers in boosting part quality, shortening cycle times, and ensuring reliable, continuous production.

Mikron Tool engineered a customized strategy and designed eight specific tools for tibial plate machining and five endmills for femoral components. The solution yields reduced machining time and which significantly reduces the post machining surface treatment time.

All the new tools feature an exclusive, innovative coating that is hard and resistant to oxidation, extreme temperatures, and wear. It reduces adhesive wear, crack formation, and chipping, resulting in extended tool life.